The powerful CNC-controlled wire bending machines for the production of bent parts from wire and profile material always offer the right solution for your products with their different series for performance and high-performance applications. From the smallest wire diameters from 1.5 mm up to large wire thicknesses up to 16.0 mm, always the right solution for all requirements. With flexible equipment variants and various additional options, WAFIOS wire bending machines cover every application economically.

Fast - Flexible - Productive

Machines

Machine comparison BM Series

- Modular machine concept for customer-specific requirements

- Broad range of products

- High degrees of freedom during bending

- High flexibility and safety thanks to reliable tool concept

- Safe and simple operation thanks to our WAFIOS Programming System WPS 3.2 EasyWay

- Reduction of tooling times by iQ Software functions

- Simple handling of the wire – from the entry area up to the bending head

Please select wire diameter [mm]

BM 36 HighSpeed

from 2

to 6.5 mm

| Wire diameter | 2 - 6.5 mm |

| Extension of wire diameter range (option) | From wire Ø 1.5 mm |

| 600 N/mm² | 2 - 6.5 mm |

| 1,200 N/mm² | 2 - 4.5 mm |

| 1,900 N/mm² | 2 - 3.6 mm |

| Bend-back clearance | 160/500/800/1,100 mm (infinite adjustment option via CNC axis) |

| Stroke, bending head (Z axis) | + 10 mm / - 80 mm |

| CNC support plate (X axis) option | Stroke. + 25 mm / - 200 mm |

| Stroke, displaceable cutting unit (@V axis) option | - |

| Lowering the bending pin, inside (K axis), option | - |

| Bending head positioning | +30° fixed |

| Feed speed | max. 140 m/min |

| Number of CNC axes | 7 (max. 14 option) |

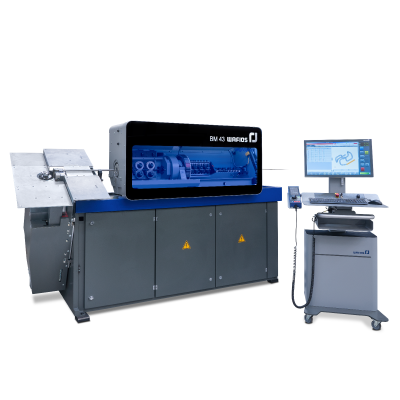

BM 43 HighSpeed

from 3

to 8 mm

| Wire diameter | 3 - 8 mm |

| Extension of wire diameter range (option) | From wire Ø 1.5 mm |

| 600 N/mm² | 3 - 8 mm |

| 1,200 N/mm² | 3 - 5 mm |

| 1,900 N/mm² | 3 - 4.3 mm |

| Feed rollers | 3 pairs |

| Bend-back clearance | 200/500/800/1,100/1,400 mm (infinite adjustment option via CNC axis) |

| Stroke, bending head (Z axis) | + 18 mm / - 122 mm |

| Transverse stroke, bending head (B axis) | + 60 mm / - 60 mm |

| CNC support plate (X axis) option | Stroke. + 25 mm / - 235 mm |

| Stroke, displaceable cutting unit (@V axis) option | 200 mm |

| Lowering the bending pin, inside (K axis), option | - 30 mm |

| Bending head positioning | +25° fixed |

| CNC support plate, stroke | +25 mm / -235 mm (option) |

| Number of CNC axes | 7 (max. 17 option) |

BM 50

from 4

to 10 mm

| Wire diameter | 4 - 10 mm |

| Extension of wire diameter range (option) | From wire Ø 2.0 mm |

| 600 N/mm² | 4 - 10 mm |

| 1,200 N/mm² | 4 - 6 mm |

| 1,900 N/mm² | 4 - 5 mm |

| Feed rollers | 4 pairs |

| Bend-back clearance | 400/ 700/ 1,000/ 1,300 mm manually adjustable |

| Stroke, bending head (Z axis) | + 25 mm / - 120 mm |

| Transverse stroke, bending head (B axis) | + 200 mm / - 100 mm |

| CNC support plate (X axis) option | +25 mm / - 235 mm |

| Lowering the bending pin, inside (K axis), option | - 25 mm |

| Bending head positioning | +30° fixed |

| Feed speed | max. 120 m/min |

| Number of CNC axes | 7 (8 / max. 14) |

BM 60

from 6

to 13 mm

| Wire diameter | 6 - 13 mm |

| Extension of wire diameter range (option) | From wire Ø 3.0 mm |

| 600 N/mm² | 6 - 13 mm |

| 1,200 N/mm² | 6 - 8.5 mm |

| 1,900 N/mm² | 6 - 7 mm |

| Feed rollers | 4 pairs |

| Bend-back clearance | 500/ 800/ 1,100/ 1,400mm (infinite adjustment option via CNC axis) |

| Stroke, bending head (Z axis) | + 100 mm / - 100 mm |

| Transverse stroke, bending head (B axis) | + 100 mm / - 50 mm |

| CNC support plate (X axis) option | + 25 mm / - 235 mm |

| Stroke, displaceable cutting unit (@V axis) option | 200 mm |

| Lowering the bending pin, inside (K axis), option | - 25 mm |

| Bending head positioning | + 25° fixed/ 0° (option) |

| Feed speed | max. 120 m/min |

| Number of CNC axes | 6 (8 / max. 18) |

BM 90

from 8

to 16 mm

| Wire diameter | 8 - 16 mm |

| Extension of wire diameter range (option) | - |

| 600 N/mm² | 8.0 mm–16.0 mm |

| 1,200 N/mm² | 8 - 12.7 mm |

| 1,900 N/mm² | 8 - 10.5 mm |

| Feed rollers | 4 pairs |

| Angle of rotation of mandrel axis | Infinite |

| Bend-back clearance | 600 - 1,350 mm manually adjustable |

| Stroke, bending head (Z axis) | + 5 mm / - 190 mm |

| Transverse stroke, bending head (B axis) | + 75 mm / - 75 mm |

| CNC support plate (X axis) option | + 50 / - 140 mm |

| Stroke, displaceable cutting unit (@V axis) option | 700 mm |

| Lowering the bending pin, inside (K axis), option | - 30 mm |

| Lowering the bending pin, outside (U axis), option | - 30 mm |

| Bending head positioning | +20° fixed |

| Feed speed | max. 65 m/min |

| Number of CNC axes | 11 / 21 |

BM 43 HighSpeed

Maximum performance for your parts

The HighSpeed machines, which include both highly dynamic drives and a 5-year license IQsmartbend, can be used to optimize unit costs across the entire range of parts. The high-end bending machine, equipped with intelligent software, optimizes all bending programs fully automatically based on its digital twin. The output of the BM 36 HS can be increased by up to 40%.

WAFIOS Technology: For Those Who Demand the Best!

Optional solutions for process optimization (iQs)

iQwire: Real-time simulation for calculating cycle times and for collision monitoring

iQwire+: Automatic calculation of a production process free from collisions, positioning of the table axis and optimized calculation of cycle times

iQinspect: Import/export of nominal geometry data and correction data from external measuring system to WAFIOS programming system WPS 3.2 EasyWay

iQbendcontrol: Visual camera system for measuring and regulating bending angles

Further information