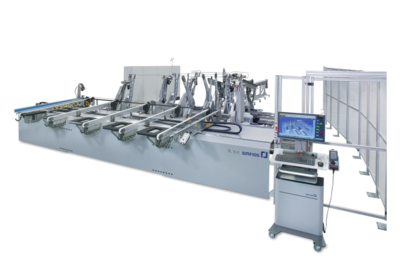

Series production of long tubes

The BL 10 CNC multiple-head tube bending machine is intended for the automated processing of brake and supply lines with a length of up to 6,000 mm and diameters of 4 – 10 mm. Depending on the scope and requirements, the modular system can be fitted with up to three bending stations and two bending heads in each case.

Machines

Machine comparison BL 10

- The special kinematics of the tube bending machine enables a broad range of parts to be produced, including parts that feature complex geometries

- Increase in output even with highly complex and unstable workpieces through automatic optimization of the bending processes and transfer of workpieces thanks to iQsmartbend (optional)

- Maximum repeat accuracy thanks to rotary-draw bending integrated in one-of-a-kind, universal, low-wear tool concept

- One-of-a-kind, innovative loading concept solves insertion problems experienced with long, unstable lines

- Reduction in unit costs due to minimized non-productive times, rapid part transfer, low-wear tool drives, space-saving machine concept, and automatic optimization of bending processes

BL 10-2

| Tube diameter | 4 - 12.7 mm |

| Bending heads | 2 pieces |

| Tube diameter, steel | |

| 400 N/mm² | 4 - 10 x 1.0 mm |

| Tube diameter, aluminum | |

| 270 N/mm² | 4 - 12.7 x 1.0 mm |

| Tube length | up to 6,000 mm |

| Extension of operating range | Option |

| Bending simulation iQtube | |

| Length measuring device | Option |

| Camera system | Option |

| Color detection device | Option |

| Displaceable auxiliary grippers | Option |

| Ext. programming station | Option |

| iQinspect measuring cell connection | Option |

| Machine control | WPS 3.2 EasyWay |

BL 10-4

| Tube diameter | 4 - 12.7 mm |

| Bending heads | 4 pieces |

| Tube diameter, steel | |

| 400 N/mm² | 4 - 10 x 1.0 mm |

| Tube diameter, aluminum | |

| 270 N/mm² | 4 - 12.7 x 1.0 mm |

| Tube length | up to 6,000 mm |

| Extension of operating range | Option |

| Bending simulation iQtube | |

| Length measuring device | Option |

| Camera system | Option |

| Color detection device | Option |

| Displaceable auxiliary grippers | Option |

| Ext. programming station | Option |

| iQinspect measuring cell connection | Option |

| Machine control | WPS 3.2 EasyWay |

BL 10-6

| Tube diameter | 4 - 12.7 mm |

| Bending heads | 6 pieces |

| Tube diameter, steel | |

| 400 N/mm² | 4 - 10 x 1.0 mm |

| Tube diameter, aluminum | |

| 270 N/mm² | 4 - 12.7 x 1.0 mm |

| Tube length | up to 6,000 mm |

| Extension of operating range | Option |

| Bending simulation iQtube | |

| Length measuring device | Option |

| Camera system | Option |

| Color detection device | Option |

| Displaceable auxiliary grippers | Option |

| Ext. programming station | Option |

| iQinspect measuring cell connection | Option |

| Machine control | WPS 3.2 EasyWay |

BL 10-2

Maximum bending freedom for maximum quality - WAFIOS BL 10 series

With extremely narrow grippers and short straight center sections, the WAFIOS BL 10 provides unique degrees of freedom for combined draw and roll bending with the narrowest contours. The modular concept with parallel work flows, rapid part transfer, minimized non-productive times, and automated optimization of the bending process reduces costs and increases productivity by up to 60%! The BL 10 only requires a very short amount of time to manufacture components with complicated three-dimensional geometries and more than 50 bends in line with the customer's requirements. The machinery system is characterized by its simple parts supply, the highest quality of individual bends, high output, and a fast, predictable return on investment.

Highest output and quality

Extremely high bending speeds, thanks to reliable technology from over 100 years of experience in wire processing transferred to tube technology, lead to increases in output. The combined rotary-draw, roll, and free-form bending it provides allows the arrangement of up to 3 bending levels and the combination of processing techniques.

Further information