Machines

Machine comparison KEH Series

- Robust machine design for the production of high-strength chains over a long period of time

- Continuous welding of all chain links in one cycle (link by link)

- Complete deburring of welding mark

- All KEH x.2 machines have a greater output due to individually adjustable rpm numbers for welding, deburring and transport

- All KEH x.2 machines have an upsetting system that is not connected with the control shaft

- Servo-hydraulic upsetting axes are used for the KEH 4.2, KEH 5.2 and KEH 7.2 machines

- A servo-cam drive is used at the KEH 3.2 and KEH 8.2 machines for driving the upsetting system

- The upsetting process can be freely programmed at the monitor. There is no mechanical upsetting cam required.

Please select wire diameter [mm]

KEH 3.2

from 3

to 6 mm

| Wire diameter | 3 - 6 mm |

| at max. 1,000 N/mm² | 3 - 5 mm |

| at max. 900 N/mm² | 3 - 6 mm |

| Inner link length (pitch) | 9 - 39 mm |

| Output, chain links | 90 - 65 pcs./min |

KEH 4.2

from 5

to 10 mm

| Wire diameter | 5 - 10 mm |

| at max. 900 N/mm² | 5 - 10 mm |

| at max. 1,000 N/mm² | 5 - 9 mm |

| Inner link length (pitch) | 13.5 - 50 mm |

| Output, chain links | 75 - 50 pcs./min |

KEH 5.2

from 8

to 13 mm

| Wire diameter | 8 - 13 mm |

| at max. 900 N/mm² | 8 - 13 mm |

| at max. 1,000 N/mm² | 8 - 12 mm |

| Inner link length (pitch) | 21.5 - 65 mm |

| Output, chain links | 55 - 34 pcs./min |

KEH 7.2

from 10

to 18 mm

| Wire diameter | 10 - 18 mm |

| at max. 1,000 N/mm² | 10 - 16 mm |

| at max. 800 N/mm² | 10 - 18 mm |

| Inner link length (pitch) | 27 - 100 mm |

| Output, chain links | 45 - 18 pcs./min |

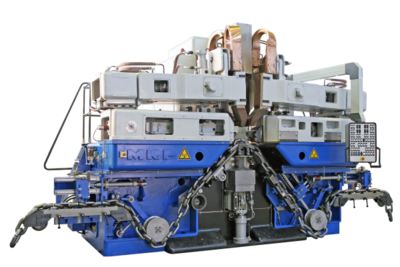

KEH 8

from 13

to 20 mm

| Wire diameter | 13 - 20 mm |

| at max. 800 N/mm² | 13 - 20 mm |

| at max. 500 N/mm² | 13 - 20 mm |

| Inner link length (pitch) | 32 - 130 mm |

| Output, chain links | 27 - 14 pcs./min |

KEH 8.2 - 23

from 16

to 23 mm

| Wire diameter | 16 - 23 mm |

| at max. 800 N/mm² | 16 - 23 mm (max. 24,2 mm ohne Plustoleranz) |

| at max. 900 N/mm² | 16 - 22 mm (max. 23,1 mm ohne Plustoleranz) |

| Inner link length (pitch) | 41.5 - 130 mm (min 2,7 x d) |

| Leistung | 23 - 10 St./min |

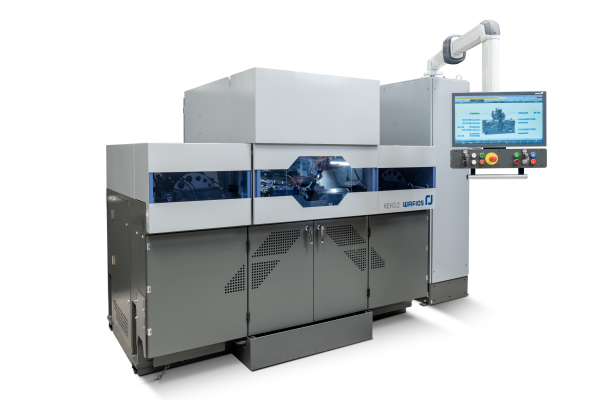

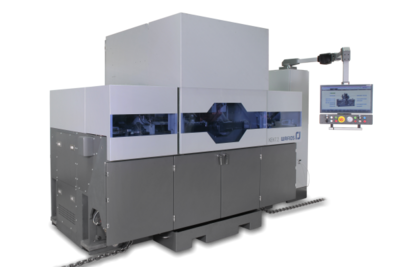

KEH 3.2

Chain welding machines for resistance butt welding round steel chains KEH series

Modern design with increased safety and operating convenience. Adjustment of operating ranges and tensile wire strengths to current market requirements, including stainless steel and adjusted to the chain bending machines KEB x.2 and KER x.2. Replacing the complicated mechanical system of control shafts with individual servodrives reduces tooling and set-up times because there is no mechanical set-up work required anymore and parameters can be saved for later use in the control system.

Consistent use of servo-technology in the new x.2 series

The threephase motor that continuously drove the control shafts has been replaced. All servoaxes movements are now made at a considerably reduced

duty cycle. Upsetting system with integrated pre-stroke by two synchronously working servo hydraulic axes. Chain is transported and rotated up/down via an electric servo-axis.