CNC Wire Bending Machines for Wire Diameters Between 1.5 mm and 16 mm

WAFIOS offers an extensive range of products for the wire processing industry. Our customized solutions involve single-head as well as multiple-head bending machines for the production of two-dimensionally and three-dimensionally bent parts. Furthermore, we offer high-precision CNC transfer bending machines equipped with several stations for bending, forming, flattening, thread-rolling and many other operations. Thus we always ensure to meet your production requirements in the best possible way - both in technical and economical terms.

Customized Solutions for Processing Wire

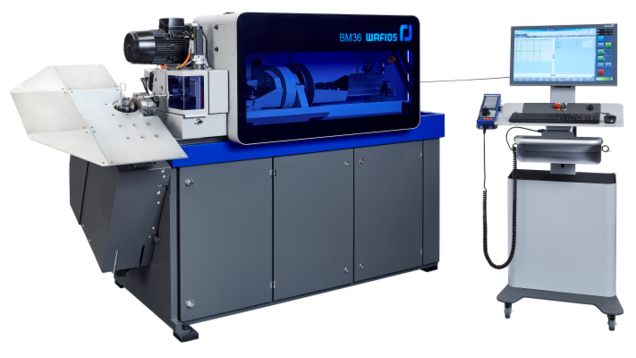

Single-Head Bending Machines

Our CNC coiling and bending machines are a precise and efficient solution for the production of two- and three-dimensionally bent parts from wire, tube and profiled materials. Thanks to highly dynamic drives, our bending machines enable an economical production of simple but also complicated parts. Due to a flexible amount of CNC axes and a large variety of options, the machines can be configured on a modular basis as required by different materials and geometries. This ensures maximum efficiency and productivity, lowers production costs and increases the quality of the products produced.

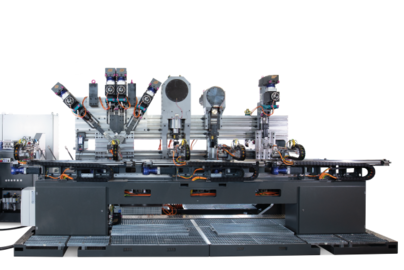

Multi-Head Bending Machines

CNC-controlled dual- and multiple-head bending machines have been designed for the production of two-dimensionally and three-dimensionally bent parts and frames from round wire, tube and profiled materials. Dynamic bending head drives and precise straightening systems offer high production efficiency. These machines allow a precise and quick production of complicated, asymmetrical and symmetrical parts. The CNC control unit ensures an economical production of large batches. Due to their flexibility and adaptability, the machines are a customized solution for different production requirements. The machines' design allows to carry out various bending processes simultaneously which increases the production speed considerably. Thus the machines are particularly well suited for the production of complicated parts needed in different industries, like the automotive, furniture, electronic or mechanical engineering industry. Due to their flexibility and adaptability, the machines also are a customized solution for different production requirements.

Transfer Bending Machine

The modular CNC transfer bending machine is equipped with several stations for bending, forming, flattening, thread rolling, and many more. The patented transfer system serves for transporting workpieces to the different stations that can be configured on a modular basis. These stations offer individual production solutions for round wire, tube and profiled materials.

Operator support for setting up new parts

Machines with assisted or automated functions help the user and make everyday processes faster. The BM 36 HS can be equipped with Operator Level 3 and thus supports operators with a fully assisted setup function.

Our Accomplishments for your Inquiry:

Feasibility Study and Technical Advice

Tool Development and Production

Automation of Processes

Sample Part Production

FAQs - Wire Bending Machines

WAFIOS wire bending machines are characterized by high precision, flexibility and innovative strength. They have been designed for the production of complicated parts from wire, tube and profiled materials and offer a multitude of advantages:

- Precision and reliability: WAFIOS machines guarantee a repeatable and exact production of parts. This makes them an ideal solution for complex applications from the automotive, furniture and electronic industry.

- Modularity and flexibility: Due to flexible CNC control units and a variable number of axes, the machines can be individually adjusted to specific requirements. This enables a broad range of two- but also three-dimensional bending operations.

- High speed and efficiency: WAFIOS offers high-speed bending machines equipped with dynamic drives and precise straightening systems. They can produce symmetrical and asymmetrical parts quickly and with high precision which shortens production times and increases the efficiency of the machines.

- Innovative technology: WAFIOS continuously invests in new technologies and innovations in order to maximize the output and operability of their machines. Examples of their innovative strength are advanced bending head drives, straightening systems and automation functions.

- Long service lives and user-friendly maintenance: The machines have a robust design and long service lives. Their design ensures quick and easy maintenance and retooling.

- Customized solutions: WAFIOS offers customized solutions that can be adapted to meet specific customer requirements and production processes. This enables a particularly efficient and economical production.

All in all, WAFIOS wire bending machines are an excellent combination of quality, flexibility, efficiency and innovative strength which makes them the ideal choice for a production of complicated parts.

WAFIOS offers a wide range of standard and specialized bending tools for their bending machines that guarantee high precision, flexibility and efficiency in the production of parts from wire, tube and profiled materials. These tool solutions can be adjusted to the according requirements and specific bending processes of customers. These are some of the most important tool solutions WAFIOS has to offer for their bending machines:

Special tools for complicated bending processes:

- WAFIOS offers special tools and appliances for demanding and complicated bending requirements. They enable a precise production of asymmetrical or particularly fine geometries. These tools can be customized in accordance with the customer's requirements.

Straightening systems:

- Straightening rollers: WAFIOS offers advanced straightening systems which have been specifically designed for an exact orientation of the wire or tube before the bending process. These systems ensure even material guidance and prevent material defects or distortions during processing.

In a nutshell: WAFIOS offers a wide range of standard and special bending tools which enable the production of a multitude of parts bent with high precision and efficiency. These tools are continuously enhanced to meet the growing demands of the industry and to make production even faster and more flexible.

WAFIOS wire bending machines use a programming software (WPS) which has been developed in-house and which ensures an easy and intuitive programming of parts. WAFIOS believes in modern software solutions for integrated quality enhancement (iQs) which optimize the entire production process and enable highest process reliability. The software's main features include:

• iQtorque • iQconvert • iQbend • iQsmartbend • iQinspect

• iQwire • iQbendcontrol • OPC-UA • Remote maintenance

- Insulation stripping device for stripping the insulation of profiled copper wire by means of a laser or milling tool (i.e. mechanically).

- Linear guides / tubular wire guide with a displaceable feed unit increase process reliability and improve the machine performance when processing soft materials.

- Process optimization iQs software function

- Servomotor-driven displacement of the feed unit for highest degrees of geometrical freedom thanks to variable bend-back clearances

- Chamfering device without extraction unit ensures an economical production of wire parts with chamfered ends

- Pointing

- Bending after the cut

- Welding unit Device serves for welding wire ends of frames and rings.

- Die forming, die cutting, end working

- Automation solutions

- Customer-specific, additional or secondary operations are available on request

WAFIOS bending machines are able to process a large range of materials suitable for the production of precise parts from bendable wire, tube and profiled materials.