Our range of spring coiling machines can accommodate every requirement, from tiny compression springs with wire diameters measuring as little as 0.12 mm right through to the other end of the scale at up to 30 mm.

Fast - Flexible - Productive

Machines

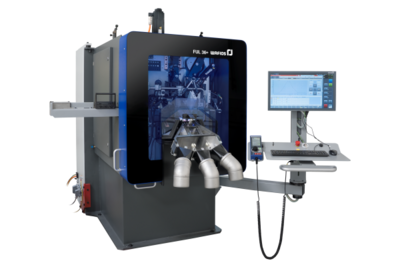

Machine comparison FUL Series

- High output, high flexibility

- Future-oriented machine concept, individual configuration for all kinds of application

- Convenient programming system WPS 3.2 EasyWay increases machine availability

- High quality standards ensure zero-defect production

- iQ Functions - Enhanced efficiency through intelligent process control

Please select wire diameter [mm]

FUL 16

from 0.12

to 0.8 mm

| Wire diameter | 0.12 - 0.8 mm |

| Wire strength | Rm = 2,600 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 20 mm |

| Coiling direction | right and left |

| Feed speed | max. 240 m/min |

FUL 16+

from 0.12

to 0.8 mm

| Wire diameter | 0.12 - 0.8 mm |

| Wire strength | Rm=2600 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 20 mm |

| Coiling direction | rechts und links |

| Feed speed | max. 260 m/min |

FUL 26+

from 0.2

to 1.6 mm

| Wire diameter | 0.2 - 1.6 mm |

| Wire strength | Rm = 2,300 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 45 mm |

| Coiling direction | Right, left as option |

| Feed speed | max. 240 m/min |

FUL26+ 4speed

from 0.5

to 1.6 mm

| Wire diameter | 0.2 - 1.6 mm |

| Wire strength | Rm = 2,300 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 45 mm |

| Coiling direction | Right, left as option |

| Feed speed | max. 240 m/min |

FUL 36+

from 0.5

to 3 mm

| Wire diameter | 0.5 - 3 mm |

| Wire strength | Rm = 2,300 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 65 mm |

| Coiling direction | Right, left as option |

| Feed speed | max. 220 m/min |

FUL36+ 4speed

from 1

to 2.8 mm

| Wire diameter | 1 - 2.8 mm |

| Wire strength | Rm = 2,300 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 65 mm |

| Coiling direction | Right, left as option |

| Feed speed | max. 500 m/min |

FUL 46

from 0.9

to 4.5 mm

| Wire diameter | 0.9 - 4.5 mm |

| Wire strength | Rm = 2,100 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 95 mm |

| Coiling direction | Left, right as option |

| Feed speed | max. 175 m/min |

FUL56

from 1.5

to 5 mm

| Wire diameter | 1.5 - 5 mm |

| Wire strength | Rm = 2,100 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 95 mm |

| Coiling direction | Right, left as option |

| Feed speed | max. 150 m/min |

FUL 76

from 2.1

to 7.5 mm

| Wire diameter | 2.1 - 7.5 mm |

| Wire strength | Rm = 2,200 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 140 mm |

| Coiling direction | right and left |

| Feed speed | max. 130 m/min |

FUL 86

from 3.1

to 8 mm

| Wire diameter | 3.1 - 8 mm |

| Wire strength | Rm = 2,000 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 150 mm |

| Coiling direction | Right, left as option |

| Feed speed | max. 130 m/min |

FUL 126

from 5.1

to 12 mm

| Wire diameter | 5.1 - 12 mm |

| Wire strength | Rm = 2,200 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 220 mm |

| Coiling direction | Right, left as option |

| Feed speed | max. 100 m/min |

FUL 166

from 6.1

to 16 mm

| Wire diameter | 6.1 - 16 mm |

| Wire strength | Rm = 2,000 N/mm² |

| Spring index | ≥5 |

| Outer spring diameter | max. 240 mm |

| Coiling direction | Right, left as option |

| Feed speed | max. 70 m/min |

FUL 175

from 6.1

to 17 mm

| Wire diameter | 6.1 - 17 mm |

| Wire strength | Rm = 2,000 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 240 mm |

| Coiling direction | Right, left as option |

| Feed speed | max. 70 m/min |

FUL 183

from 8.1

to 18 mm

| Wire diameter | 8.1 - 18 mm |

| Wire strength | Rm = 2,000 N/mm² |

| Spring index | ≥5 |

| Outer spring diameter | max. 300 mm |

| Coiling direction | Right |

| Feed speed | max. 70 m/min |

FUL 203

from 8.1

to 20 mm

| Wire diameter | 8.1 - 20 mm |

| Wire strength | Rm = 2,000 N/mm² |

| Spring index | ≥5 |

| Outer spring diameter | max. 300 mm |

| Coiling direction | Right |

| Feed speed | max. 65 m/min |

FUL 226

from 12.1

to 30 mm

| Wire diameter | 12.1 - 30 mm |

| Wire strength | Rm = 800 N/mm² |

| Wire diameter | 12.1 - 22 mm |

| Wire strength | Rm = 2,000 N/mm² |

| Outer spring diameter | max. 300 mm |

| Spring index | ≥4 |

| Coiling direction | Right, left as option |

| Feed speed | max. 65 m/min |

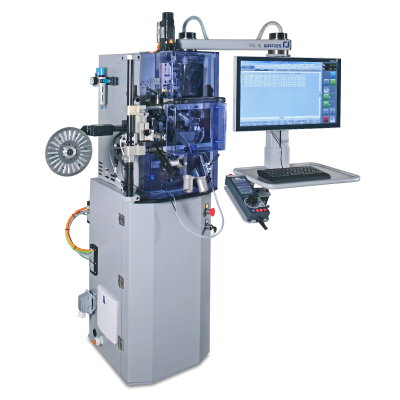

FUL 16

- Standard machine with 7 CNC axes (8 CNC axes max.)

- Direct drive on infeed, form axis, and cut for improved accuracy and production rate

- Powerful infeed with 1 pair of feed rollers (optionally 2 pairs)

- Servomotor-driven mandrel height adjustment and mandrel displacement

- Vertical pitch and parallel pitch

- Robust cutting unit with rotary and straight cut

- - PTP coiling finger for initial tension control (option)

- Coiling pin holder with additional fine adjustment

- Increased output due to new "optimized 2" cut

Further information

Coiling Roller with Mounting Fixture – The Alternative to Stationary Coiling Tools

(All)

Download

(PDF, 190 KB)

Coiling Pins with PCD Insert - Processing Stainless Steel Wire Economically

(All)

Download

(PDF, 978 KB)

RE-GRINDING lohnt sich- bis zu 70% Kostenersparnis ihr Nachschleifservice für Abschneidedorne

(German)

Download

(PDF, 282 KB)

RE-GRINDING pays off - Cost savings of up to 70% Your regrinding service for cutting mandrels

(All)

Download

(PDF, 278 KB)

Drehbarer Rollendrahtführung – Optimiert für die Verarbeitung von Profildraht

(German)

Download

(PDF, 751 KB)

Coiling Roller with Mounting Fixture – The Alternative to Stationary Coiling Tools

(All)

Download

(PDF, 190 KB)