WAFIOS is showcasing innovative bending solutions for wires and tubes at Global Industrie 2025. The company’s combination of tradition and innovative strength has made it a market leader in mechanical engineering. Its extensive product range covers more than 130 machine types and includes machines for spring manufacturing, wire and tube processing and producing hairpins and busbars. The exhibition will feature the BM 36 HS HighSpeed wire bending machine in combination with the new FSA 2.5 insulation stripping device and the BMZ 8, a CNC tube bending machine for complicated, bent tube parts.

Achieving perfect bending results at high speed

The BM 36 HS is a high-speed wire bending machine that provides a great deal of freedom during the bending process. The high-end bending machine is equipped with intelligent software and optimizes all bending programs fully automatically as required based on digital twins. The result is an output increase of up to 40 percent compared to the predecessor machine, depending on the geometry in question. The modular system can be configured exactly in line with customer requirements. The bending machine is suitable for wire diameters of 1.5 to 6.5 mm.

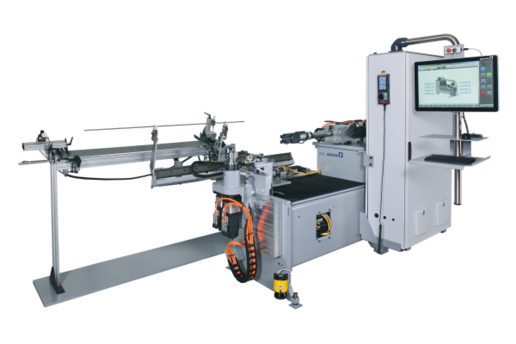

At Global Industrie, the BM 36 HS will be on show together with the FSA 2.5 insulation stripping device, designed for stripping enamel-insulated round copper wire. Applications include electronic connectors, such as those used in electric motors or in power electronics. The insulation stripping device has a radially defined feed for the stripping knives, provided by a servomotor, and ensures that the coating is removed reliably and the copper material is removed as defined.

The user-friendly design enables the indexable inserts with PCD cutting edges to be changed quickly. The WPS 3.2 EasyWay programming system provides a convenient and straightforward solution when it comes to programming and entering parameters. The clean and efficient stripping process ensures that no additional processing is required.

The BM 36 HS is ideal for electronics, the automotive sector, the furniture industry, shopfitting, domestic appliance production and many other applications.

Maximum precision with intelligent technology

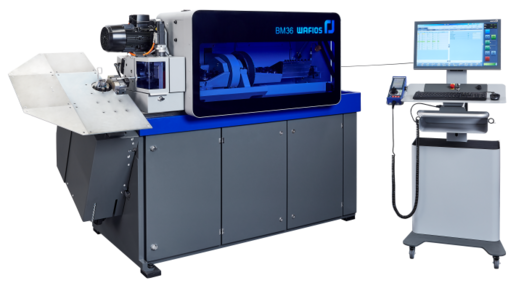

Small bending radii in fluid lines are particularly in demand in the automotive sector, as vehicle engine compartments have little space and demand the highest quality standards. With the BMZ 8 single-head tube bending machine, manufacturers can rise to challenges like this with ease. Special jaws make it possible to make bends close to the tube end – ideal for producing fluid lines in the automotive industry, such as brake lines.

The BMZ series is based on a successful and reliable concept. Designed from the very beginning for the production of complicated bent parts from cut-to-length, partially ready-to-install tubes with processed ends, the WAFIOS BMZ series has been setting standards in the market for years.

The proven technology was carried over from wire processing to tube technology and features impressively high bending speeds. The combined rotary-draw, roll and free-form bending it provides allows the arrangement of up to three bending levels and the combination of processing techniques. This makes it possible to bend protective casings at the same time. The basic scope includes right and left bending in one clamping process, allowing even complicated two and three-dimensional workpieces to be manufactured in a single cycle.

The 3D bending technology with special jaws for extremely short lengths can accommodate geometrically complex components with minimal final lengths. The highly compact tool structure makes it possible to form special parts with spirals or bend-in-bend geometries. Using the simulation feature, components can be tested and adjusted before production, cutting down on costs. With automatic optimization byiQsmartbend, process-related vibrations can be analyzed and adjusted automatically. This has the benefit of keeping vibrations to a minimum, resulting in a significant increase in throughput.