Our range of spring coiling machines can accommodate every requirement, from tiny compression springs with wire diameters measuring as little as 0.12 mm right through to the other end of the scale at up to 30 mm.

Fast - Flexible - Productive

Machines

Machine comparison FSE & F Series

- Modular, customized equipment options

- Reduced costs due to modular design, energy efficiency and optimized tooling times

- Machine takes up little space, enabling optimum factory planning and plant logistics

- Economic output due to high availability

- Flexibility thanks to space-saving machine concept

Please select wire diameter [mm]

F 08

from 0.12

to 0.8 mm

| Wire diameter | 0.12 - 0.8 mm |

| Wire diameter at Wm 6 or Rm max. 2,600 N/mm² | 0.12 - 0.6 mm |

| Wire diameter at Wm 4 or Rm max. 2,300 N/mm² | 0.6 - 0.8 mm |

| Outer spring diameter | max. 20 mm |

| Coiling direction | right and left |

| Feed speed | max. 160 m/min |

F 12

from 0.2

to 1.2 mm

| Wire diameter | 0.12 - 0.8 mm |

| Wire diameter at Wm 4 or Rm max. 2,500 N/mm² | 0.2 - 1.1 mm |

| Wire diameter at Wm 5 or Rm max. 1,800 N/mm² | 1.1 - 1.2 mm |

| Outer spring diameter | max. 20 mm |

| Coiling direction | rechts und links |

| Feed speed | max. 160 m/min |

F 18

from 0.35

to 1.8 mm

| Wire diameter | 0.35 - 1.8 mm |

| Wire diameter at Wm 4 or Rm max. 2,300 N/mm² | 0.35 - 1.6 mm |

| Wire diameter at Wm 4 or Rm max. 1,900 N/mm² | 1.6 - 1.8 mm |

| Outer spring diameter | max. 40 mm |

| Coiling direction | rechts und links |

| Feed speed | max. 140 m/min |

FSE 15

from 0.12

to 0.8 mm

| Wire diameter | 0.12 - 0.8 mm |

| Wire strength | Rm = 2,600 N/mm² |

| Spring index | ≥ 4 |

| Outer spring diameter | max. 20 mm |

| Coiling direction | right and left |

| Feed speed | max. 150 m/min |

FSE 143

from 6.1

to 14 mm

| Wire diameter | 6.1 - 14 mm |

| Wire strength | Rm = 2,000 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 240 mm |

| Coiling direction | Right |

| Feed speed | max. 70 m/min |

F 30

from 0.7

to 3 mm

| Wire diameter | 0.7 - 3 mm |

| Wire diameter at Wm 4 or Rm max. 2,000 N/mm² | 0.7 - 2.5 mm |

| Wire diameter at Wm 6 or Rm max. 1,800 N/mm² | 2.5 - 3 mm |

| Outer spring diameter | max. 65 mm |

| Coiling direction | Right, left as option |

| Feed speed | max. 135 m/min |

F 4

from 1.5

to 4.5 mm

| Wire diameter | 1.5 - 4.5 mm |

| Wire diameter at Rm max. 2,000 N/mm² | 1.5 - 4 mm |

| Wire diameter with Rm max. 1,800 N/mm² | 1.5 - 4.5 mm |

| Outer spring diameter | max. 100 mm |

| Coiling direction | right and left |

| Feed speed | max. 100 m/min |

F 6

from 2.6

to 7 mm

| Wire diameter | 2.6 - 7 mm |

| Wire diameter at Rm max. 2,000 N/mm² | 2.1 - 6 mm |

| Wire diameter with Rm max. 1,800 N/mm² | 2.1 - 7 mm |

| Outer spring diameter | max. 130 mm |

| Coiling direction | right and left |

| Feed speed | max. 100 m/min |

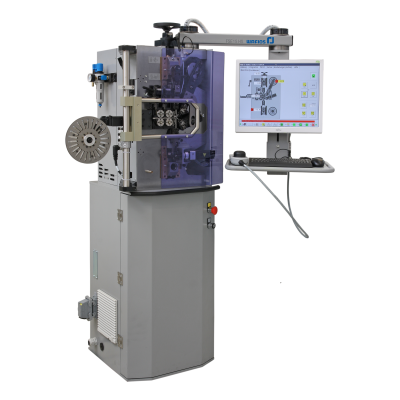

FSE 15

- Fully fledged compression spring coiler as standard version, modular expansion options

- Optimum unit costs in compression spring production

- High availability thanks to reliable and proven machine control plus easy-to-maintain design

- High-performance development with extended range of applications

- Precision thanks to the latest measuring and control technology

- Shorter set-up time and greater operating convenience

Further information