Powerful Solutions for Electric Drives

Hairpins are bent parts made of insulated, enameled copper wire. They are used in the modern electric motors found in electric cars, hybrid vehicles, and e-bikes, where they replace the wound inductor coils that are part of conventional stators. Hairpin motors improve the power-to-weight ratio due to the packing density of the profile material.

WAFIOS offers state-of-the-art bending technology for producing hairpins, covering everything from small batches up to high volumes.

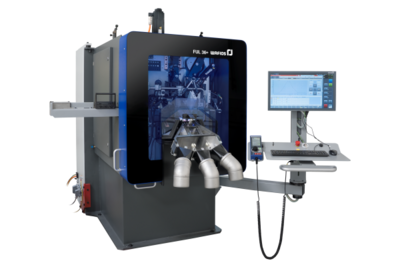

Machines

Machine comparison FUL Series

- High output, high flexibility

- Future-oriented machine concept, individual configuration for all kinds of application

- Convenient programming system WPS 3.2 EasyWay increases machine availability

- High quality standards ensure zero-defect production

- iQ Functions - Enhanced efficiency through intelligent process control

Please select wire diameter [mm]

FUL 16

from 0.12

to 0.8 mm

| Wire diameter | 0.12 - 0.8 mm |

| Wire strength | Rm = 2,600 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 20 mm |

| Coiling direction | right and left |

| Feed speed | max. 240 m/min |

FUL 16+

from 0.12

to 0.8 mm

| Wire diameter | 0.12 - 0.8 mm |

| Wire strength | Rm=2600 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 20 mm |

| Coiling direction | rechts und links |

| Feed speed | max. 260 m/min |

FUL 26+

from 0.2

to 1.6 mm

| Wire diameter | 0.2 - 1.6 mm |

| Wire strength | Rm = 2,300 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 45 mm |

| Coiling direction | Right, left as option |

| Feed speed | max. 240 m/min |

FUL26+ 4speed

from 0.5

to 1.6 mm

| Wire diameter | 0.2 - 1.6 mm |

| Wire strength | Rm = 2,300 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 45 mm |

| Coiling direction | Right, left as option |

| Feed speed | max. 240 m/min |

FUL 36+

from 0.5

to 3 mm

| Wire diameter | 0.5 - 3 mm |

| Wire strength | Rm = 2,300 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 65 mm |

| Coiling direction | Right, left as option |

| Feed speed | max. 220 m/min |

FUL36+ 4speed

from 1

to 2.8 mm

| Wire diameter | 1 - 2.8 mm |

| Wire strength | Rm = 2,300 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 65 mm |

| Coiling direction | Right, left as option |

| Feed speed | max. 500 m/min |

FUL 46

from 0.9

to 4.5 mm

| Wire diameter | 0.9 - 4.5 mm |

| Wire strength | Rm = 2,100 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 95 mm |

| Coiling direction | Left, right as option |

| Feed speed | max. 175 m/min |

FUL56

from 1.5

to 5 mm

| Wire diameter | 1.5 - 5 mm |

| Wire strength | Rm = 2,100 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 95 mm |

| Coiling direction | Right, left as option |

| Feed speed | max. 150 m/min |

FUL 76

from 2.1

to 7.5 mm

| Wire diameter | 2.1 - 7.5 mm |

| Wire strength | Rm = 2,200 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 140 mm |

| Coiling direction | right and left |

| Feed speed | max. 130 m/min |

FUL 86

from 3.1

to 8 mm

| Wire diameter | 3.1 - 8 mm |

| Wire strength | Rm = 2,000 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 150 mm |

| Coiling direction | Right, left as option |

| Feed speed | max. 130 m/min |

FUL 126

from 5.1

to 12 mm

| Wire diameter | 5.1 - 12 mm |

| Wire strength | Rm = 2,200 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 220 mm |

| Coiling direction | Right, left as option |

| Feed speed | max. 100 m/min |

FUL 166

from 6.1

to 16 mm

| Wire diameter | 6.1 - 16 mm |

| Wire strength | Rm = 2,000 N/mm² |

| Spring index | ≥5 |

| Outer spring diameter | max. 240 mm |

| Coiling direction | Right, left as option |

| Feed speed | max. 70 m/min |

FUL 175

from 6.1

to 17 mm

| Wire diameter | 6.1 - 17 mm |

| Wire strength | Rm = 2,000 N/mm² |

| Spring index | ≥4 |

| Outer spring diameter | max. 240 mm |

| Coiling direction | Right, left as option |

| Feed speed | max. 70 m/min |

FUL 183

from 8.1

to 18 mm

| Wire diameter | 8.1 - 18 mm |

| Wire strength | Rm = 2,000 N/mm² |

| Spring index | ≥5 |

| Outer spring diameter | max. 300 mm |

| Coiling direction | Right |

| Feed speed | max. 70 m/min |

FUL 203

from 8.1

to 20 mm

| Wire diameter | 8.1 - 20 mm |

| Wire strength | Rm = 2,000 N/mm² |

| Spring index | ≥5 |

| Outer spring diameter | max. 300 mm |

| Coiling direction | Right |

| Feed speed | max. 65 m/min |

FUL 226

from 12.1

to 30 mm

| Wire diameter | 12.1 - 30 mm |

| Wire strength | Rm = 800 N/mm² |

| Wire diameter | 12.1 - 22 mm |

| Wire strength | Rm = 2,000 N/mm² |

| Outer spring diameter | max. 300 mm |

| Spring index | ≥4 |

| Coiling direction | Right, left as option |

| Feed speed | max. 65 m/min |

FUL 166

High output, high flexibility

- Configuration of machine ensures a fast production of springs due to a high feed speed, excellent axis acceleration values and very short cutting times

- Different types of cuts are available

- Versatile equipment options

Future-oriented machine concept

- Latest drive and control technology

- Modular machine structure and innovative tool solutions

High-end programming system WPS 3.2 EasyWay

increases the availability of your machine

- Programming of geometries for simplified spring input

- Manual settings can be saved with the spring program

High quality standards ensure zero-defect production

- Optical measuring of product with subsequent adjustment

- Further process control features like e.g. slip control and color marking identification

- iQautopitch for faster repeat set-up of springs, in combination with a measuring system

Further information