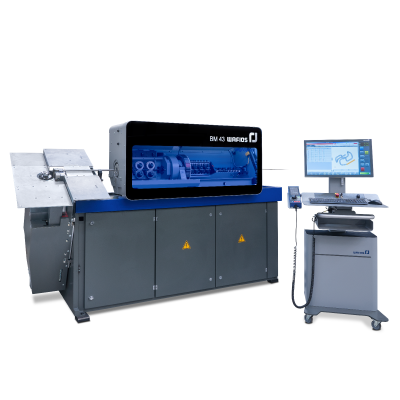

The powerful CNC-controlled wire bending machines for the production of bent parts from wire and profile material always offer the right solution for your products with their different series for performance and high-performance applications. From the smallest wire diameters from 1.5 mm up to large wire thicknesses up to 16.0 mm, always the right solution for all requirements. With flexible equipment variants and various additional options, WAFIOS wire bending machines cover every application economically.

Fast - Flexible - Productive

Machines

Machine comparison BMU Series

- Universal machine concept

- Very broad range of products

- High degrees of freedom during bending

- Rotary straightening for highly precise products

- High flexibility and safety thanks to reliable tool concept

- Safe and simple operation thanks to our WAFIOS Programming System WPS 3.2 EasyWay

- Reduction of tooling times by iQ Software functions

- Simple handling of the wire – from the entry area up to the bending head

Please select wire diameter [mm]

BMU 40

from 3

to 8 mm

| Wire diameter | 3 - 8 mm |

| Extension of wire diameter range (option) | From wire Ø 1.5 mm |

| 600 N/mm² | 3 - 8 mm |

| 1,200 N/mm² | 3 - 5 mm |

| 1,900 N/mm² | 3 - 4 mm |

| Feed rollers | 3 pairs |

| Angle of rotation of mandrel axis | Infinite |

| Angle of rotation of bending axis | Infinite |

| Bending head travel up/down | +25 mm / -120 mm |

| Bending head, transverse stroke at 0° position | +200 mm / -200 mm |

| Bending head, transverse stroke at 30° position | +200 mm / -100 mm |

| Servomotor-adjustable bend-back clearance | 400 - 1300 mm adjustable |

| Bending head positioning | +30° / 0° (manually) |

| CNC support plate, stroke | +25 mm / -235 mm (option) |

| Feed speed | 120 m/min |

| Bending moment | approx. 520 Nm |

| Number of CNC axes | max. 24 |

BMU 50

from 4

to 10 mm

| Wire diameter | 4 - 10 mm |

| Extension of wire diameter range (option) | From wire Ø 2.0 mm |

| 600 N/mm² | 4 - 10 mm |

| 1,200 N/mm² | 4 - 6 mm |

| 1,900 N/mm² | 4 - 5 mm |

| Feed rollers | 4 pairs |

| Angle of rotation of mandrel axis | Infinite |

| Angle of rotation of bending axis | Infinite |

| Bending head travel up/down | +25 mm / -120 mm |

| Bending head, transverse stroke at 0° position | +200 mm / -200 mm |

| Bending head, transverse stroke at 30° position | +200 mm / -100 mm |

| Servomotor-adjustable bend-back clearance | 400 - 1300 mm adjustable |

| Bending head positioning | +30° / 0° (manually) |

| CNC support plate, stroke | +25 mm / -235 mm (option) |

| Feed speed | 120 m/min |

| Bending moment | approx. 1,050 Nm |

| Number of CNC axes | max. 24 |

BMU 40

Highly flexible machine concept covers a very large range of parts

The BMU series has been tried and tested over many years on the market and during this time many trendsetting innovations have been added to the machine concept. Today, the combination of proven and innovative design has proved to be the basis for the BMU's success on the market. High availability, performance, flexibility and long machine service life make the BMU a future-oriented machine, offering high investment security and value retention of many years.

Now even more flexible thanks to more extensive configuration options

The BMU series is based on a modular concept and thus offers a wide range of options.

The very robust design of the machine body and the machine's very high process reliability guarantee a continuously high quality of the parts produced. Its range of products and - due to optimized tools - increased output of special bent parts as well a numerous options for special operations, like die forming, chamfering, welding and punching, meet all requirements.

Further information