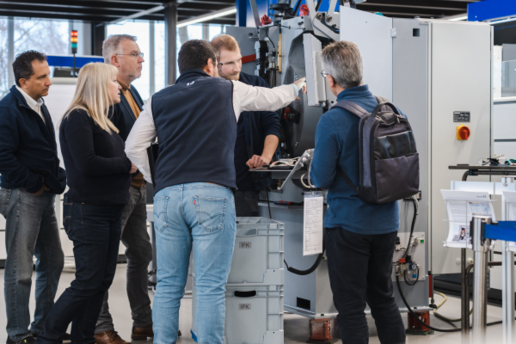

The WAFIOS Innovation Days are now firmly established in the calendar as a technology event focusing on wire and tube processing. The last in-house exhibitions of this nature went down extremely well with the specialists who attended, despite taking place under difficult conditions due to the pandemic. WAFIOS is therefore planning an even bigger event this year which will surpass its predecessors in numerous respects – with live contact opportunities, animated discussions, and plenty of hardware to get your hands on. “The 2023 Innovation Days will be the largest in-house exhibition we have ever held at our Reutlingen headquarters,” says Dr.-Ing. Uwe-Peter Weigmann, Speaker of the Board. With this major event, WAFIOS is combining the in-house exhibition in Wuppertal with the in-house exhibition in Reutlingen. This means that more than 35 machines will be available for presentations. All WAFIOS product areas will be presented: Wire bending, compression spring / extension spring / wave spring and torsion spring production, straightening, chain welding, e-mobility applications, and tube bending.

In the field of spring production alone, there will be 13 machines on display from the latest generation. The focus will be on recent developments, such as 4speed technology in the field of compression springs with a maximum feed speed of 600 m/min or the FUL 126 with adaptive controllers for springs up to 12mm diameter. With many other smaller improvements such as a new sensor-controlled reject sorting device, spring experts are sure to get their money’s worth. Another new development is a fully integrated spring end grinding machine from the G series – the automatic spring feeding device with robot effectively forms one unit with the subsequent setting and measuring steps.

When it comes to the material feed, WAFIOS will be demonstrating new developments for the tried-and-tested pay-off unit solutions – for example, with regard to residual weight detection and with an overhauled pay-off unit concept with spring rod deflections, which enables a space-saving setup.

Technological Highlights at the Exhibition

The highlights of this year’s Innovation Days will include five completely new developments from WAFIOS that are being presented to the industry for the first time:

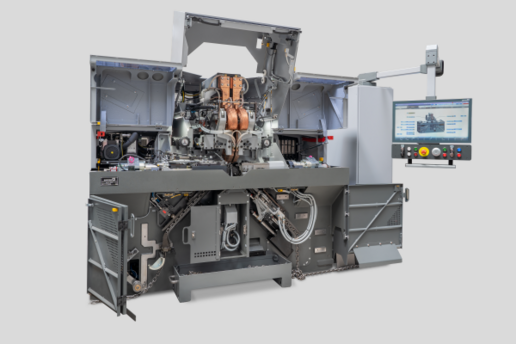

The BMF 90busbar machine can process larger cross-sections than ever before. With this innovation, the product developers are responding to a trend toward short loading times and more powerful drives. In both cases, suitable connections with a larger cross-section are required. In addition, demand for aluminum busbars is growing due to their weight – the variants with the largest cross-sections are increasingly being made from this light metal. The BMF 90 is designed to form material with dimensions from 12 x 3 mm to 50 x 4 mm. “The application field of busbars, which is still relatively new, is closely linked to wire forming. We therefore see an opportunity for companies in this field to expand their portfolio on a long-term basis,” says Dr.-Ing. Uwe-Peter Weigmann.

Alongside the BMF machine series, the event will also mark the world premiere of a new WAFIOS unit for stripping insulation mechanically using a patented method for the purposes of busbar contacting. This solution is much more cost-effective than the alternative of using a laser to strip insulation. The unit is also designed for flexibility, as it is suitable for a whole range of cross-sections up to max. 200 mm² or 50 x 4 mm. The cycle times for insulation stripping are reduced by approx. 40%, making it possible to achieve a higher output for the machine as a whole.

The TWISTER² series is also being expanded: TWISTER² 35 RL is the new robot-assisted bending solution for tubes with dimensions of up to 35 x 2 mm or comparable rectangular cross-sections. One possible application for this solution is tube/hose combinations with attachment parts as used in hydraulic systems and air conditioning technology. When combined with the innovative tube gripper device, the robot solution offers more flexibility during processing.

Another application is high-voltage busbars for electric vehicles. Manufacturers are increasingly designing these components to be longer and more complex, as they often run through the trunk of the car. A cost-effective manufacturing solution is essential in order to make pre-assembled components available in greater quantities.

The BMZ 6 from WAFIOS is a new bending solution for tubes and cables with diameters of 0.5 to 6.35 mm. In addition, this space-saving machine is also suitable for wires. Application examples include lubrication lines in plant engineering, cannulas in medical technology, or coaxial cables in high-frequency technology. Particularly in the case of coaxial cables, WAFIOS is tapping into a completely new application field with the BMZ 6.

In the field of chain welding machines, WAFIOS will be presenting the latest improvements to the familiar KEH 3.2. The machinery system now features state-of-the-art servo and control technology, and the output has increased by 15 to 20%. The use of medium-frequency welding technology also results in further performance enhancements. For the diameter range of 3 to 6 mm, the approval for wire tensile strength has increased by 20% to max. 900 N/mm². In the diameter range of 3 to 5 mm, the value is max. 1,000 N/mm².

New Software for Industry 4.0

In addition to the many new machines and machine developments, WAFIOS will also be presenting various software innovations in its Services division:

The Innovation Days will see the launch of the new webshop for spare parts. This will supplement the existing tool shop and make it possible to procure standard components more quickly.

There are two new products related to Industry 4.0: “Fingerprint” and “Condition Monitoring”. Both solutions are used to either diagnose faults quickly or to detect them at an early stage so that action can be taken before they lead to stoppages. Fingerprint makes it possible to diagnose the axis status in order to speed up machine commissioning and help in the case of servicing. The new Condition Monitoring system allows operators to monitor the condition of the machine during production and is the first step toward predictive maintenance.

Reduced Tool Costs with Modular Solutions

The modular cutting tool for large spring coiling machines reduces tool costs as only the wearing part is replaced rather than the entire tool. The modular bending mandrel for torsion spring machines from the FMU series offers maximum flexibility in production, as special tools are simply made from standardized pre-prepared parts without having to produce the entire bending mandrel.

The 2023 Innovation Days will also see a record number of co-exhibitors. A total of ten companies – more than ever before – will be presenting their products and solutions: WAFIOS Umformtechnik, E.W. Menn, WAFIOS Tube Automation, Böhm Elektronik, iT Engineering, imess, Hexagon, Theleico, Roland Electronic, Dreisbach & Jungmann.