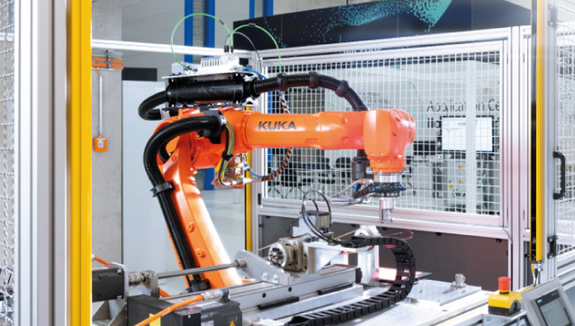

… at RWTH Aachen University was founded in 2014 by "StreetScooter" co-founder Professor Achim Kampker. In ten research groups, the team is dedicated to all aspects of the development, production and recycling of battery systems and their components as well as the fuel cell and the production of the electric drive train and entire vehicle concepts. The research group "Electric Drive Production" contributes to the economic, variant-flexible, future-oriented and sustainable production of the electric drive and its active components (rotor and stator). The focus is on investigating issues along the entire value chain - from the semi-finished product to the finished drivetrain and from the individual process to the holistic consideration of cross-process interactions. In accordance with the PEM philosophy of the "Innovation Chain", the team works on new and innovative technologies, always keeping an eye on the path to industrial application and solution scaling. Current topics of the research group are:

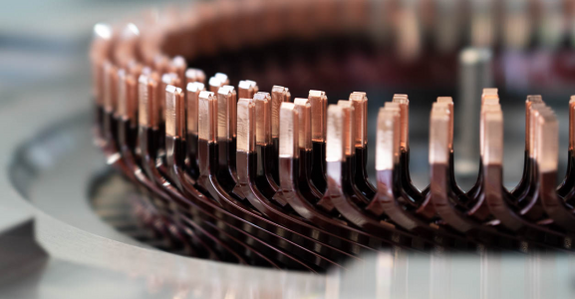

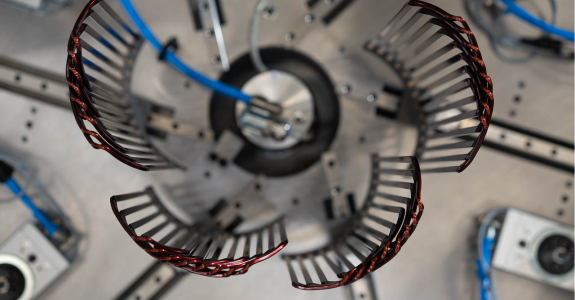

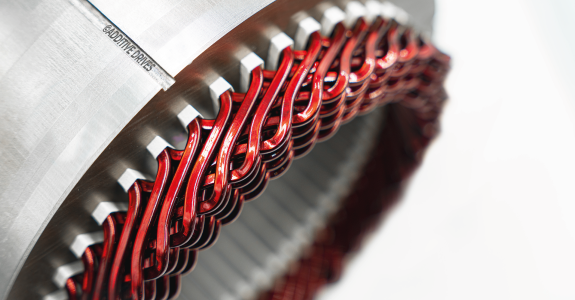

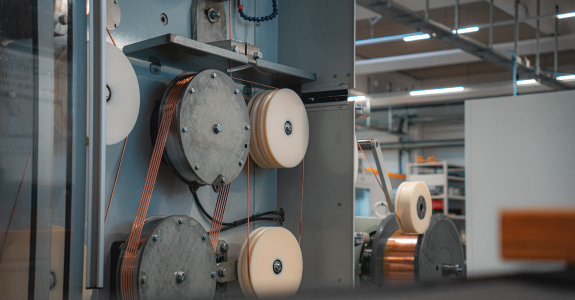

- Interdependencies between semi-finished product and process in stator production (with special focus on stripping, bending & welding).

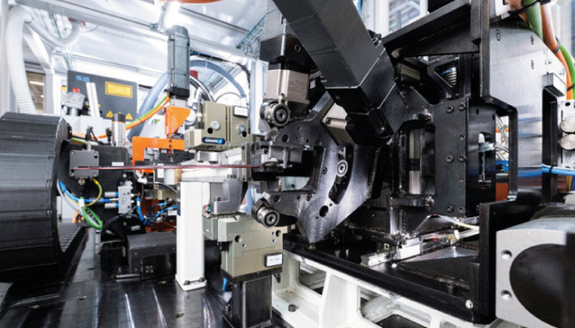

- Development and implementation of application-oriented test and inspection procedures as a basis for demand-oriented products and processes

- Lifecycle-oriented optimization of production processes and development of measures to identify and reduce the CO2 footprint along the entire value chain

- Use of AI-based methods for efficient, economical and sustainable electric motor production

![[Translate to English:] BMF 90](/fileadmin/user_upload/WAFIOS/NEWS/Events/Ausstellung/red/Bilder/Grafik_BTF.png)

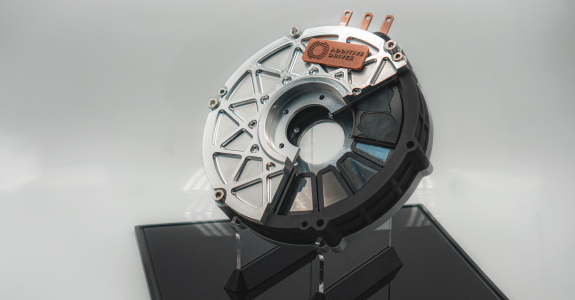

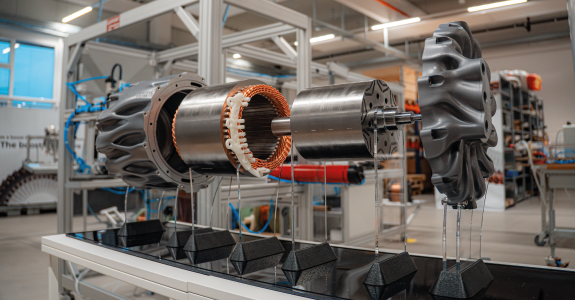

![[Translate to English:] Additive Drives](/fileadmin/user_upload/WAFIOS/NEWS/Events/Events_2024/Additive_Drives_04.png)

![[Translate to English:] Logo Hexagon](/fileadmin/user_upload/WAFIOS/NEWS/Events/Ausstellung/red/Bilder/Hexagon_004.png)

![[Translate to English:] Logo Hexagon](/fileadmin/user_upload/WAFIOS/NEWS/Events/Ausstellung/red/Bilder/Hexagon_005.png)

![[Translate to English:] Logo Hexagon](/fileadmin/user_upload/WAFIOS/NEWS/Events/Ausstellung/red/Bilder/Hexagon_006.png)

![[Translate to English:] KEYENCE](/fileadmin/user_upload/WAFIOS/NEWS/Events/Ausstellung/red/Bilder/KEYENCE_1.png)