EasyRobot manages the handling of delicate workpieces well. WAFIOS has integrated the robot made by KUKA directly into the WPS 3.2 EasyWay programming system. Thus it can be operated like the WAFIOS machine. Expensive robot training courses for employees are therefore a thing of the past.

The industry's rising quality and packaging requirements go hand in hand with the rising requirements on the handling of finished springs and bent wire and tube parts. These parts, for example, have to be placed in a defined position in special transport containers or they have to be removed from the machine's tool room without damaging their surface. More and more, industrial robots are used to carry out tasks that formerly were carried out manually, by simple transport systems or conventional workpiece slides. WAFIOS follows this trend and integrates the KUKA robot of the Agilus and Cybertech series completely into the WAFIOS programming system WPS 3.2 EasyWay. The EasyRobot sets new benchmarks in the operation of machines.

Integration into WAFIOS programming system

Many WAFIOS CNC machines for the production of springs and bent wire and tube parts (fig. 1) can now be operated together with the robot via the machine's control unit. This merges the production program for the spring or the bent part with the robot program. Due to the integration into the WAFIOS programming system WPS 3.2 EasyWay, the robot does not have to be set up separately anymore and operators do not need special training courses to learn how to program the robot.

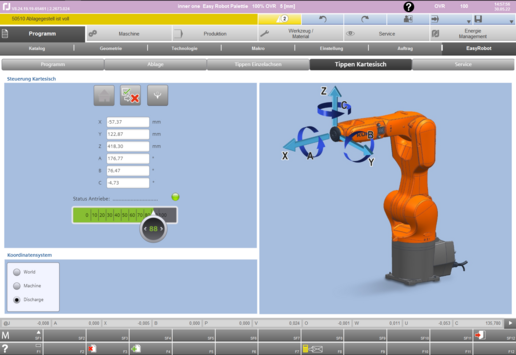

User guidance and programming of robot movements takes place on the machine's touchscreen monitor (fig. 2). All sequences performed by the robot can be implemented directly in the program of the machine. The robot axes can be conveniently moved using the machine's hand-held operating device.

The robot program is saved together with the bending program and can be reloaded as required. The robot forms a safe and CE-compliant overall system with the machine.

The EasyRobot does not only have a pick-and-place program but also special functions like palletizing and job lists.

New benchmarks in robot applications

In addition to the ready-to-operate robot, the overall scope of EasyRobot includes the entire periphery, such as base, power supply, collision protection and parallel gripper. The robot complies with CE regulations and thus ensures safe operation.

Depending on the version, EasyRobot is either integrated into the machine structure (see fig. 4) or it is adapted specifically to the machinery system (see fig. 3).

Thanks to the complete integration of the industrial robot into the production process, the EasyRobot considerably reduces the programming time of bending programs that include handling tasks and it reduces the costs for special robot training of operators.

With EasyRobot, WAFIOS sets new benchmarks in the field of robot applications for simple handling tasks. This makes cost-effective and easy-to-use robotic solutions accessible at a new level and thus also very attractive for SMEs.

As an official KUKA system partner, WAFIOS AG continues to offer complete and customized automation solutions.